First of all, it's important to know that there are three types of motor used in central vacuum cleaners: Tangential Bypass, Thru-Flow and Peripheral Bypass. However, Drainvac does not use Peripheral Bypass motors. Whatever the type of motor, each is fitted with a pair of carbon brushes held in contact with the rotor by springs.

Brush wear varies with the frequency of use of the central vacuum. For weekly use, we recommend checking their condition after 500 hours of operation, which translates to approximately every 5 to 7 years.

WARNING - We strongly recommend that you have your vacuum cleaner inspected by a certified dealer before any work is carried out, to preserve the validity warranty. Otherwise, the following text explains how to replace the carbon brushes on the main motors used by Drainvac. Although the steps and components may vary slightly depending on the motor model, the replacement principle remains the same for all Drainvac central vacuums.

Before you begin

- Make sure the unit is unplugged.

- Wear latex gloves or other hand protection to avoid grease deposits on the carbon brushes that could lead to combustion.

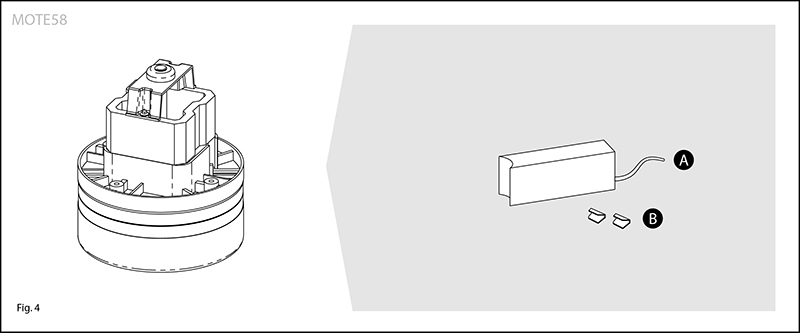

Bypass Motor par Ametek (MOTE04)

- Remove the motor's cover (Fig.1-A) by pushing out the metal latches (Fig.1-C). Then use a flathead screwdriver to release the cover's hooks on both sides.

- Unscrew both screws (Fig.1-B) on the support flange (Fig.1-C).

- Lift the brush out (Fig.1-D).

- Using a flathead screwdriver, remove the contact wire by applying pressure.

- At this stage, check to see if the rotor is in good condition. If the brush is too worn, it may have scratched the rotor. In that case, the motor must be replaced. If the rotor is scratch-free, a new brush may be installed.

- Re-assemble the carbon brush to the motor by reversing steps 4 to 2.

- Repeat steps 2 to 4 to replace the second brush.

- Replace the cover on the motor, ensuring that it is correctly clipped on both sides.

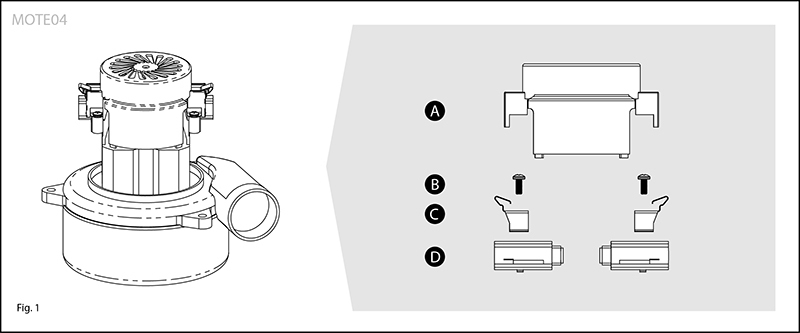

Bypass Motor by Domel (MOTE22)

- Using a flathead screwdriver, remove the cover (Fig.2-A) by releasing the hooks on both sides.

- Straighten the terminal (Fig.2-D) which connects the contact wire to the brush.

- Using a flathead screwdriver, remove the terminal by exerting pressure on the lock.

- Unscrew both screws (Fig.2-B).

- Lift the brush out (Fig.2-C).

- At this stage, check to see if the rotor is in good condition. If the brush is too worn, it may have scratched the rotor. In that case, the motor must be replaced. If the rotor is scratch-free, a new brush may be installed.

- Re-assemble the carbon brush to the motor by reversing steps 4 to 2.

- Repeat steps 2 to 5 to replace the second brush.

- Replace the cover on the motor, ensuring that it is correctly clipped on both sides.

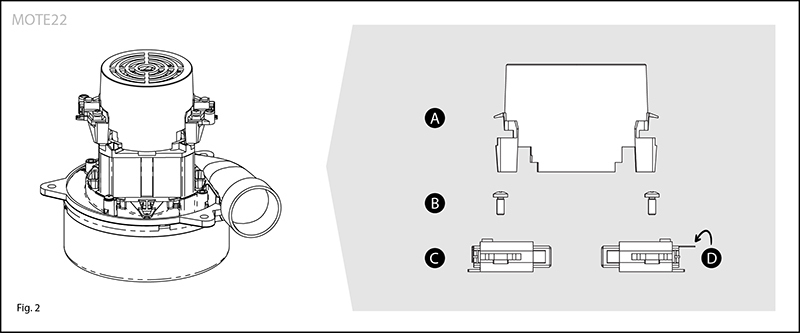

Thru-Flow Motor by Domel (MOTE38)

- Straighten the connector tip (Fig.3-B) that connects the contact wire to the brush.

- Using a flathead screwdriver, remove the terminal.

- With the same screwdriver, lower the tab (Fig.3-A) at the top that holds the brush in place.

- At this point, check if the rotor is in good condition. If the brush is too worn, it may have scratched the rotor. In that case, the motor must be replaced. If the rotor is scratch-free, a new brush may be installed.

- Reassemble the carbon brush to the motor by reversing steps 3 to 1.

- Repeat steps 1 to 3 to replace the second brush.

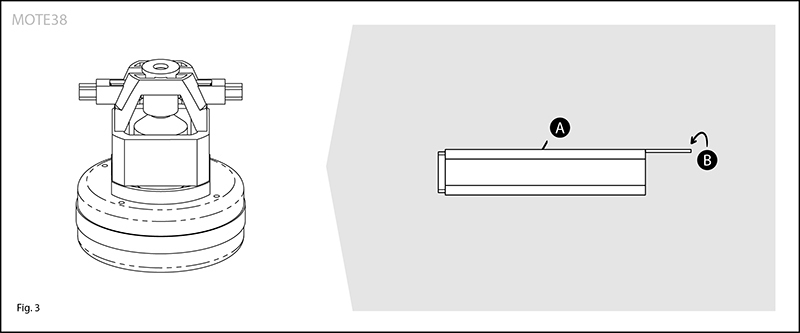

Thru-Flow Motor by Lamb (MOTE58)

- Unclip the spring holding the brush in place. CAUTION: handle the spring with care, as it is not attached to the frame and may get lost inside the motor.

- Cut the brush cord.

- Cut the copper cable clamp supplied with the new brushes into two equal parts (Fig.4-B).

- Connect the existing cord with the new brush cord (Fig.4-A) using the cable clamp, pinching both ends together.

- Place the brush on the motor, with the curved side inwards and the cord facing outwards.

- Using a pair of pliers, clip the spring onto the brush to hold it against the rotor.

- Repeat the procedure for the second brush.