A proper piping installation is essential to ensure the smooth operation of a central vacuum system. Thoughtful planning will not only maximize suction power while maintaining airflow, but also ensure comfortable, ergonomic operation while reducing the risk of clogging and maintenance requirements.

Planning the network

The first step is to plan the piping network according to the layout of the space to be covered. It's crucial to assess specific needs, taking into account the size of the building, room layout and potential obstacles. The aim is to minimize total pipe length and the number of sharp turns that can lead to airflow loss. A linear, centralized design is ideal, as it maintains a balance between the various suction intakes, ensuring consistent performance in all areas.

Special features for vacuuming liquids

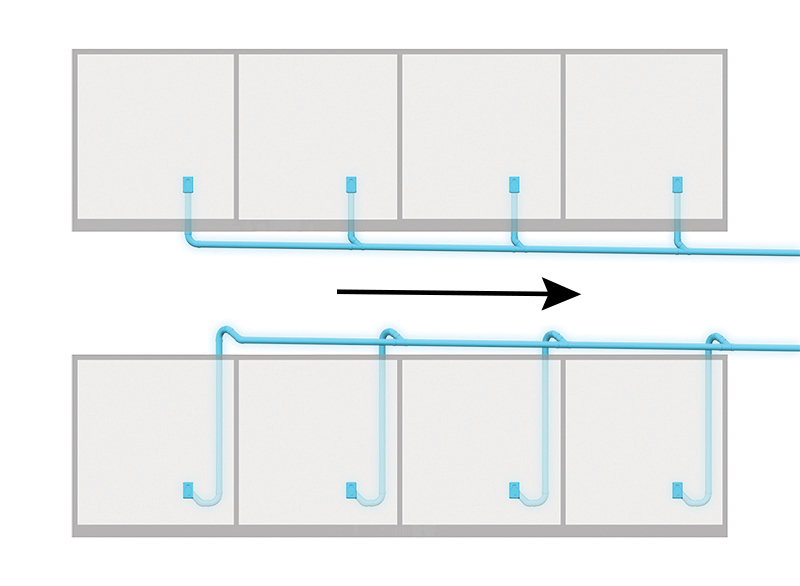

With a system designed to extract liquids, piping lines must be configured to prevent any risk of backflow. The installation of the main horizontal lines must be slightly inclined towards the unit to encourage the movement of liquids. In addition, if an inlet is positioned lower than the main line, it is essential to install a P-trap at the very beginning of the inlet. An additional loop should also be added at the highest point, where this inlet connects to the main line.

Inlet position

The location of the vacuum inlets are also an important aspect of the installation. They must be strategically positioned to cover the maximum surface area with the minimum number of pipes. This means taking into account hard-to-reach areas, multiple floors and frequently-used locations. Good planning can reduce hose length, making the system more practical and efficient. To ensure that your configuration is optimal, use the hose intended for actual use and carry out a practical test by moving from one end to the other.

Piping material

PVC pipes are generally used for central vacuum systems because of their durability. Flexible hoses are strongly discouraged, except in specific cases such as the use of special accessories (like the Vacpan), as they can lead to pressure losses and reduce system efficiency. Drainvac also offers metal pipes, DWV and XFR, to meet the needs of companies requiring the cleaning of particular materials, providing solutions for demanding applications.

Reducing angles and curves

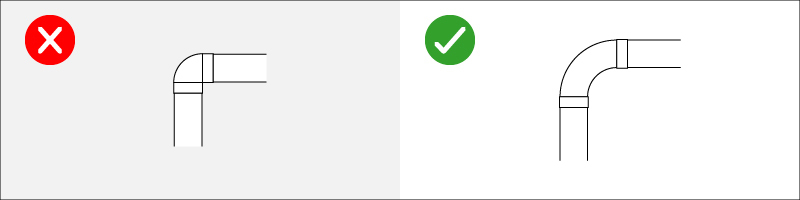

Angles and curves in the ducting network can cause turbulence that reduces suction power. With the exception of wall inlets, 45° elbows or long 90° elbows are preferable to short 90° elbows, as the latter are more likely to create areas where debris can accumulate. By optimizing pipe layout and limiting changes of direction, air flow is smoother and more efficient.

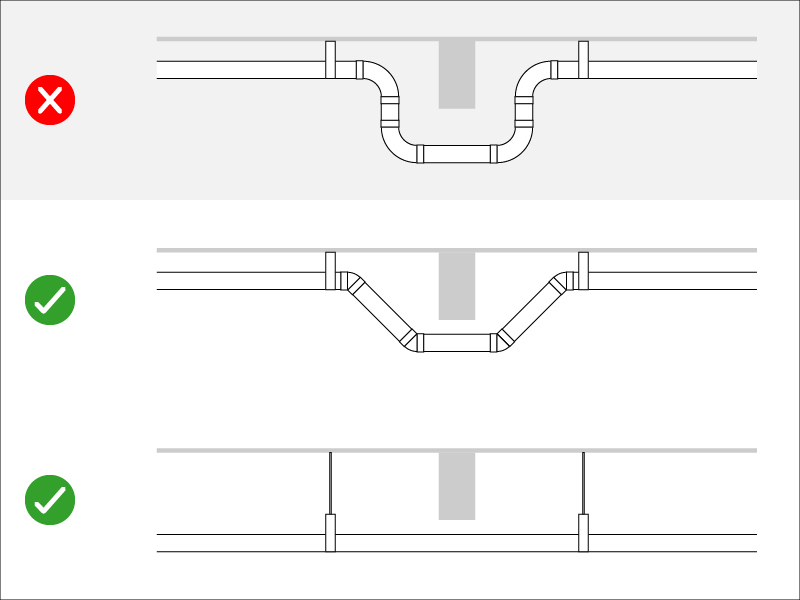

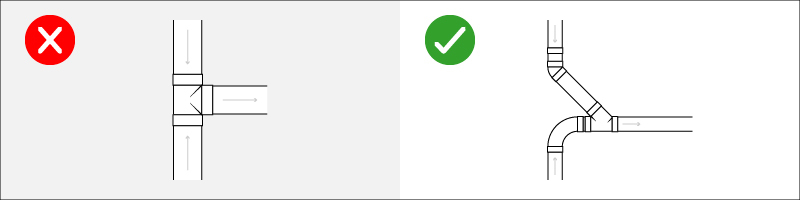

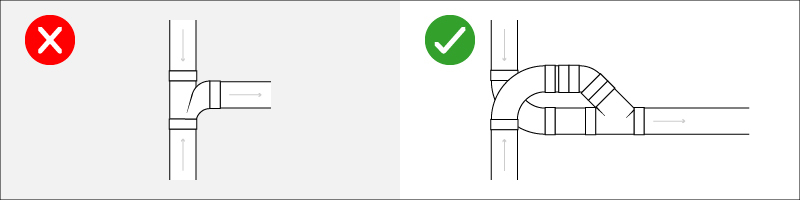

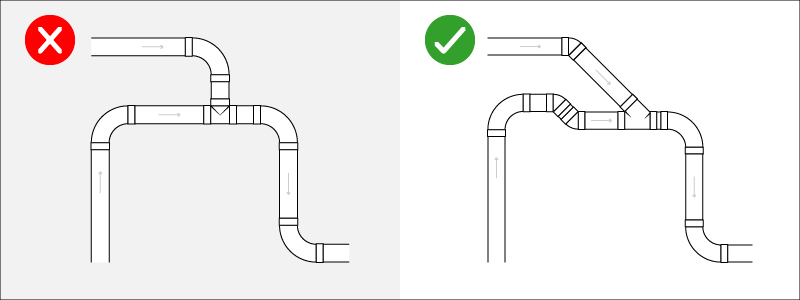

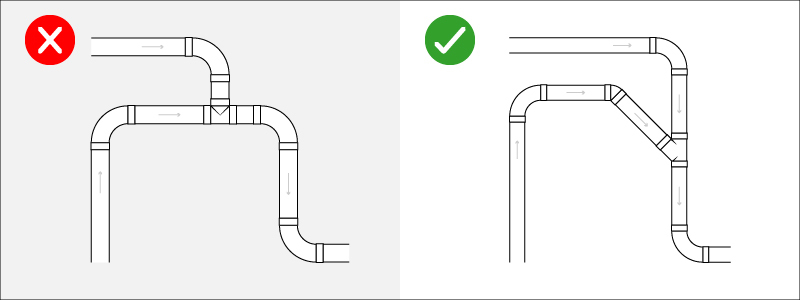

Here are some examples of good and bad installations:

Always use long-radius elbows, except for wall outlets.

Always opt for a linear installation.

Junction of 2 vertical lines for dry installation only.

Junction of 2 vertical lines for dry and liquid installation.

Junction of 2 parallel lines for dry installation only.

Connection of 2 parallel lines for dry and liquid installation.

Sealed connections

To ensure a hermetically sealed system, each fitting must be secured with glue or shrink sleeve specially designed for the type of piping used. The use of hose clamps is strongly discouraged, especially for systems capable of extracting liquids.

Maintenance

For a residential installation equipped with a dry system, no specific maintenance is required. However, if your system is designed to extract liquids, it is advisable to vacuum a significant quantity of hot water after each use, then leave the unit running for a few moments to dry the ducts. This procedure helps to thoroughly clean the pipes, remove any residues and prevent unpleasant odours, ensuring optimal, hygienic operation.

In a commercial context using a water system, Drainvac offers water and air purging systems that automate the maintenance process. However, if these purge systems are not installed, it is strongly recommended to vacuum a significant quantity of hot water at the end of each working day or week. This preventive practice helps to keep ducts in good condition and avoid repairs.

By following these recommendations, you'll optimize the operation of your central vacuum system, reaping the benefits of greater efficiency and more comfortable use. Every aspect of the installation contributes directly to the system's overall performance, ensuring that your investment is both profitable and sustainable.